Applications

Airport, Sewage Treatment Plants, Desalination Plants, Independent Power Projects, Oil & Gas Sector, Food & Beverages, Chemical Plants, Textile Industries, Paper Industries, Marine, Ship Building, Dry Docks, Railways, etc.,

Features

- Heavy Load Applications

- Light Weight with high loading strength

- Chemical Resistance

- Maintenance Free

- Anti-Slip

- Fire Retardant

- Non-Conductive

- Easy Installation

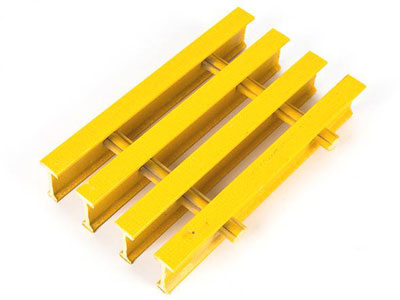

Pultruded Gratings

Arabian Gratings FRP Series Pultruded Gratings are made with pultruded (I, T, and HL) shaped profiles and mechanically interlocked with solid rods or tubes. It has a high percentage of glass fiber roving soaked with resin and finally designed to desired shapes by heating and pultrusion. Pultruded gratings are good alternate compared to steel gratings due to its features like lightweight, antifire, chemical & UV resistance, low maintenance cost, etc.

Resins Available

- Polyester Resin

- Isophthalic Resin

- Vinyl Ester Resin

- Phenolic Resin

Glass Fibre Types

- Continuous unidirectional fibers

| Type | Height (mm) (T) | Top edge width (mm) (A) | Space Between (mm) (B) | Clearence width (mm) (C) | Open Area (%) | Estimated Weight (kg/m3) |

| I-4010 | 25 | 15 | 25 | 10 | 40 | 17.1 |

| I-5010 | 25 | 15 | 30 | 15 | 50 | 14.2 |

| I-6010A | 25 | 15 | 38 | 23 | 60 | 11.2 |

| I-6010B | 25 | 8 | 19.8 | 11.8 | 60 | 12.2 |

| I-4015 | 38 | 15 | 25 | 10 | 40 | 22 |

| I-5015 | 38 | 15 | 30 | 15 | 50 | 19.1 |

| I-6015 | 38 | 15 | 38 | 23 | 60 | 16.2 |

| I-4012 | 30 | 15 | 25 | 10 | 40 | 18.8 |

| I-5012 | 30 | 15 | 30 | 15 | 50 | 15.7 |

| I-6012 | 30 | 15 | 38 | 23 | 60 | 12.6 |

| I-40125 | 32 | 15 | 25 | 10 | 40 | 19.8 |

| I-50125 | 32 | 15 | 30 | 15 | 50 | 17.4 |

| I-60125 | 32 | 15 | 38 | 23 | 60 | 13.5 |

| I-4020 | 50 | 15 | 25 | 10 | 40 | 28.5 |

| I-5020 | 50 | 15 | 30 | 15 | 50 | 24.2 |

| I-6020 | 50 | 15 | 38 | 23 | 60 | 20.1 |

| T-1210 | 25 | 38 | 43.4 | 5.4 | 12 | 14.5 |

| T-1810 | 25 | 38 | 50.8 | 9.5 | 18 | 13.8 |

| T-2510 | 25 | 38 | 50.8 | 12.7 | 25 | 12.3 |

| T-3310 | 25 | 41.3 | 19.7 | 61 | 33 | 11.2 |

| T-3810 | 25 | 38 | 61 | 23 | 38 | 10.2 |

| T-1215 | 38 | 38 | 43.3 | 5.2 | 12 | 19.6 |

| T-2515 | 38 | 38 | 50.8 | 12.7 | 25 | 16.7 |

| T-3815 | 38 | 38 | 61 | 23 | 38 | 14.2 |

| T-3320 | 50 | 25.4 | 38.1 | 12.7 | 33 | 20.3 |

| T-5020 | 50 | 25.4 | 50.8 | 25.4 | 50 | 15.7 |